From The Railway Magazine, August 1963 – The Hunslet Engine Co. develops an underfeed stoker and gas producer system which completely eliminates the emission of dark smoke.

In many industries the emission of dark smoke from steam shunting locomotives presents of the most awkward problems in the prevention of pollution to meet the requirements of the Clean Air Act.

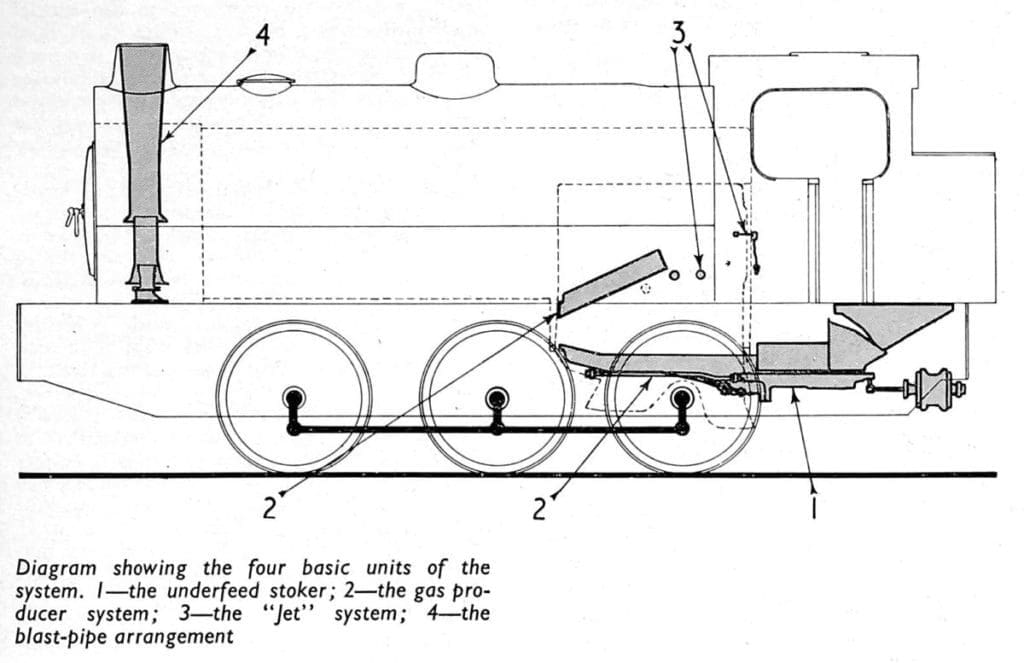

To overcome this problem the Hunslet Engine Co. Ltd.. Has developed an underfeed stoker and gas producer system which completely eliminates the emission of dark smoke. And also allows small coal (down to 1/2-in. singles) to be used, with considerable savings in fuel costs. The locomotive’s power output is also increased as a result of reduced backpressure in the cylinders. The system comprises four basic sets of components, which have been specifically designed to operate harmoniously in producing a maximum of fuel availability and economy. a minimum of cylinder back- pressure giving improved performance, and the absolute minimum of grit and smoke. The four units are the underfeed stoker, the gas producer system., the “jet” system, and the blast pipe arrangement.

Enjoy more Steams Days Magazine reading every month.

Click here to subscribe & save.

The small grate area available makes it impossible for the normal stationary type of underfeed Stoker to burn a sufficient weight of fuel to maintain the high rate of steaming necessary to retain the locomotive as an efficient and economic unit. Quite apart from the complication of the forced draft blower‘ that is required. A new approach was necessary and, after much experiment. a method of feeding the maximum amount of coal which the boiler required was evolved. Together with an arrangement of final feed which allowed the coal to be spread accurately over the whole of the firebox grate. Giving the best conditions for smoke-free combustion.

With this new design any amount of coal can be tired without difficulty, and with one class of locomotive the 0-6-0 18-in, “austerity” the Stoker fitted feeds up to 2.000 lb. of coal per hour. The operation contrives a hot thick fire at the back and sides of the firebox where it is most useful, with a rocking and drop grate in the centre forward section of the grate, to which the burnt material naturally gravitates and can then be dropped into the ash pan by a simple operation of the rocking lever. Basically the underfeed stoker consists of a reciprocating plate to which motion is imparted by a steam cylinder, which is in turn controlled by a valve mechanism.

One of the problems associated with underfeed stoking and the use of small coal is “clinkering”. This is avoided by the introduction of steam to the ash pan. The steam is supplied from the locomotive exhaust and the stoker exhaust, as well as a small amount of “live” steam which can either be used continuously, depending on the “clinkering” properties of the coal being used, or as a stand-by when the locomotive is standing. The function of this steam is to ensure a relatively cool fire bed, with the actual burning of the gases taking place above the fire bed and in the firebox. This lowered temperature prevents the formation of “clinker” and ensures that the fire remains clean and free moving.

To ensure the complete combustion of the producer gas thus formed a special arch secures the maximum use of the firebox volume and this, together with ample secondary air and the necessary turbulence, completes the combustion very much better than has ever been achieved on any locomotive previously.

The turbulence referred to be especially necessary when the locomotive is working hard with a heavy blast, and stoking heavily, or when being lighted up from cold. To cope with these conditions a system of steam jets and ports to admit secondary air to the firebox has been designed so as to give a forward flow over the fire and back up under the brick arch, during which period even the worst smoke conditions can be controlled.

To complete the review of combustion techniques as applied to the steam locomotive, conditions within the smoke box were examined.

The newly-developed design meets basic requirements: aerodynamically efficient ducts entrain maximum gas volume for minimum steam How: a new blower makes use of the same flow arrangement; the divided equal-area and streamlined exhaust flow from each cylinder give a major reduction in back pressure; and a smoke box tuning device allows smoke box draught to be matched to the type of fuel being used. The chimney has been fitted with a distinctive type of cowl. Now in regular production, the whole equipment has been developed in service over the last two years and provides an interesting example of a builder’s approach to and solution of one of the long standing and rather complex problems common to the steam locomotive. The success of the system will provide many old engines with a new lease of life.